Pickup Truck Body Structure: Load-Bearing VS Non-Load-Bearing

- Categories:BLOGS

- Author:JMC

- Time of issue:2022-10-26 10:58

- Views:0

(Summary description)After years of development in the pickup truck industry, the choice of models is very diverse. The versatility of pickup trucks makes more and more people pay attention to comfort and load-carrying functions, so as to make comprehensive considerations. The pickup trucks on the market are mainly based on non-load-bearing body structures, but more and more pickup truck brands have begun to produce load-bearing body pickups.

So what's the difference between a load-bearing body and a non-load-bearing body? This article will introduce in detail.

Pickup Truck Body Structure: Load-Bearing VS Non-Load-Bearing

(Summary description)After years of development in the pickup truck industry, the choice of models is very diverse. The versatility of pickup trucks makes more and more people pay attention to comfort and load-carrying functions, so as to make comprehensive considerations. The pickup trucks on the market are mainly based on non-load-bearing body structures, but more and more pickup truck brands have begun to produce load-bearing body pickups.

So what's the difference between a load-bearing body and a non-load-bearing body? This article will introduce in detail.

- Categories:BLOGS

- Author:JMC

- Time of issue:2022-10-26 10:58

- Views:0

After years of development in the pickup truck industry, the choice of models is very diverse. The versatility of pickup trucks makes more and more people pay attention to comfort and load-carrying functions, so as to make comprehensive considerations. The pickup trucks on the market are mainly based on non-load-bearing body structures, but more and more pickup truck brands have begun to produce load-bearing body pickups.

So what's the difference between a load-bearing body and a non-load-bearing body? This article will introduce in detail.

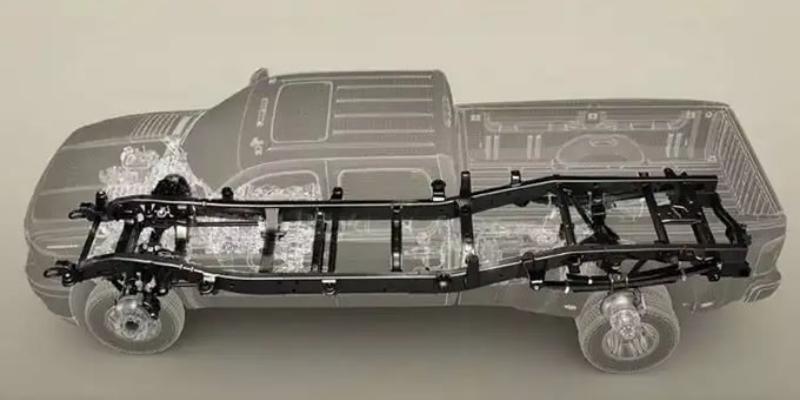

Non-load-bearing Body Structure

The non-load-bearing body literally means that the frame body does not directly or fully bear the impact. There is an independent "beam" under the frame body to bear the force from all directions. The power system and the running system are integrated and installed in the body. On a frame, the frame is then used as the base of the whole vehicle assembly and connected with the body. The non-load-bearing chassis generally adopts a rectangular or trapezoidal style. Two longitudinal beams extend from the front to the rear of the vehicle. The number and position of the beams vary according to the technical characteristics of each manufacturer. The frame is generally made of sturdy steel pipes, which are arranged horizontally and vertically and welded together. With the continuous upgrading of manufacturing techniques, a considerable proportion of high-strength and ultra-high-strength steels will be used to provide sufficient torsion resistance and bearing capacity.

Non-load-bearing is the most commonly used body structure frame for pickup trucks and is also the most widely used design in the history of the automotive industry.

Before the 1980s, almost all automotive products used non-load-bearing structures, and the load-bearing structures gradually became mainstream with the continuous development and improvement of the front-drive layout.

The horizontal front-drive mode greatly reduces the cost of large-scale production, and at the same time, the utilization of space is more efficient. After the advantages of low cost and high comfort of the load-bearing structure are gradually revealed, the torsional rigidity and high bearing capacity of the non-load-bearing body make it always the first choice for off-road vehicles, pickups and other vehicles.

The frame body and the independent beam of the non-load-bearing model are mostly flexible connections. The impact force generated during off-road or heavy load mainly acts on the chassis beam, and part of the force will be transmitted to the frame body part through the shock absorption and buffer components. The body mainly provides Crash protection and shock absorption. Since most of the force is absorbed by the extremely high-strength chassis girder, and the frame body is flexible, the torsional deformation of the body is very small, which can greatly reduce the force distortion and metal fatigue of the frame body, allowing the vehicle to perform high-load motion. can have sufficient stability, durability and safety.

A good off-load pickup is not easy to build. First of all, the frame and the body are two independent systems, and the frame is a plane structure, and the body is a cage structure, so the energy absorption and collapse of the upper and lower parts of the non-load-bearing vehicle when faced with various impacts are two types. Different forms, if not well combined, will inevitably lead to secondary damage. Secondly, the mechanical structure of the power system of the non-load-bearing vehicle is more complex. The gearbox, rear axle, drive shaft transfer case, front axle and front half shaft are all mechanical structures. With the popularity of electronic components, more On the contrary, the mechanical structure means high cost.

Load-bearing Body Structure

The load-bearing type and the non-load-bearing type are relative concepts. The load-bearing design eliminates the need for an independent chassis. The frame is both the body and the chassis. It completely relies on the frame body to withstand the impact and load of the undulating road surface. Therefore, the design of the load-bearing structure is more difficult. The requirements for strength and structural design are higher. The load-bearing structure is mostly stamped from steel plates, and the overall strength is improved by stacking multiple layers of steel plates, and a special geometric structure is used to differentiate the force to achieve the purpose of improving the flexibility and rigidity of the frame. Due to the cancellation of the independent girder design, the load-bearing body can effectively lower the chassis and make the position of the engine, transmission and suspension closer to the ground. Therefore, the use of the load-bearing body has more advantages in terms of fuel economy and control. Utilization is also better.

The load-bearing structure endows the vehicle with high integrity through flexible design, making the vehicle more suitable for driving on roads with good road conditions, and providing sufficient comfort and safety protection for drivers and passengers, but the pursuit of flexibility is also doomed. Sufficiently rigid structure for shocks that are not paved. Metal materials are not worried about hard collisions, but they are very worried about bending and twisting. Due to the lack of rigid resistance structures, the load-bearing body can only rely on flexible metal stretching to resist the impact force. High-frequency unbalanced torsion will cause metal fatigue in the body steel , so that the light and thin steel plate metal structure of the load-bearing body "becomes loose", that is, the vehicle will also appear "osteoporosis" with use.

Nearly 90% of in-service failures in metal components and structures are caused by fatigue with cyclic stress magnitudes well below the tensile strength of the materials involved, often subject to massive cumulative, irreversible damage during cyclic deformation. Under the action of alternating pressure, after a period of time, the mechanical parts will form tiny cracks in the local high stress area, and then the tiny cracks will gradually expand to break, which will affect the driving quality of the vehicle in light, and may cause deformation of the frame in severe cases. Fatigue damage has the characteristics of suddenness in time, locality in location and sensitivity to environment and defects, so fatigue damage is often difficult to be discovered in time and easy to cause accidents.

However, this does not mean that the load-bearing structure is completely isolated from the off-road environment. Although the gap between the physical structures is difficult to surpass through technical means, it can be approached infinitely. As technology continues to develop, so does the overall strength of the load-bearing body. Therefore, in theory, as long as the body strength is large enough, the load-bearing body can also be close to the experience of the non-load-bearing body, which can achieve both urban driving and off-road road conditions.

Read More:

Top 10 China Truck Manufacturers 2022

Top 10 China Pickup Brands 2021 ( Sales List )

Scan the QR code to read on your phone

Relevant Information

MESSAGE

WRITE A MESSAGE TO US

Copyright: Jiangling Motors Corporation Group GAN ICP 17001991-1 www.300.cn

Copyright: Jiangling Motors Corporation Group